The Business Need

MedImmune is the biologics arm of AstraZeneca, producing two marketed biopharmaceutical products, FluMist® (Influenza Vaccine Live, Intranasal) and Synagis® (palivizumab). Accordingly, the company is both highly technical and highly regulated. They’ve grown from 2,600 employees in 2007 to 4,200 today. With constant changes in the industry, MedImmune’s leadership wanted all employees within Operations, regardless of functional role, to have a common foundation of the what, how, and why of their work.

There were three basic goals for this learning program. First, everyone needed to understand the key concepts behind the science and manufacturing MedImmune performs in a controlled environment so supporting behaviors could be instituted and defined. Second, after studying some quality issues, MedImmune found that the common cause was a basic lack of understanding of fundamentals – people knew what to do but not why it was done that way, which led to an inability to react to unexpected issues. Third, MedImmune wanted to expand people’s perspective in applying knowledge in the interest of a larger goal. People needed to understand more than “only their piece.” They needed breadth as well, so they could see the context of where all their pieces fit.

The Solution

When the project began in 2008, the MedImmune team wanted it to be co-owned by the business, as they are the subject matter experts. They commissioned a team of cross-organizational and cross-level SMEs and engaged them in the vision, current and desired future states, and approach. They also did a targeted needs assessment with potential end users and received great feedback that identified not only the knowledge areas to cover, but also the priority of those areas, and they built that into the plan. An example of this is the gap in understanding of critical aspects of the facilities themselves, which was foundational and became part of the first phase.

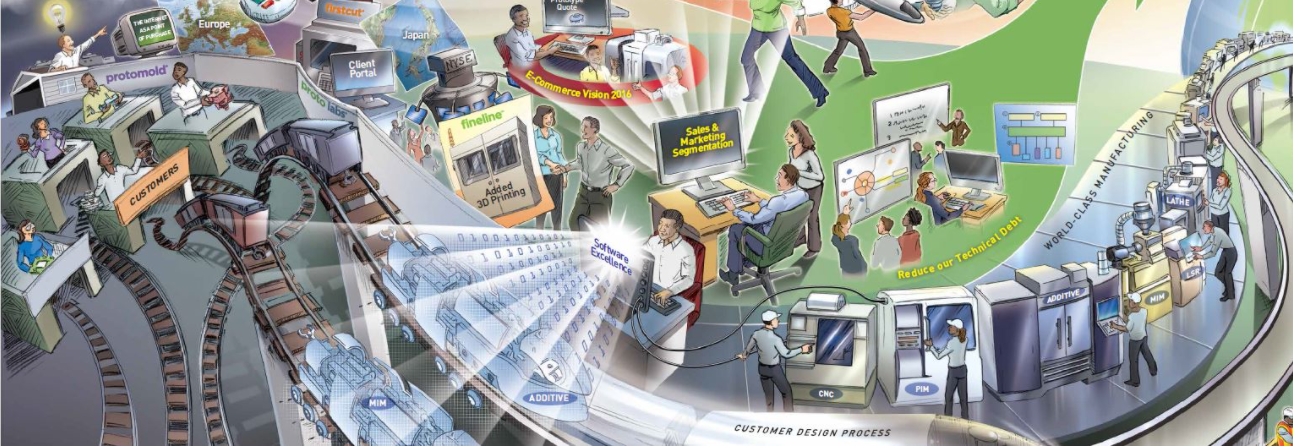

The team initially planned for electronic modules on knowledge areas, but quickly incorporated two Learning Map® modules to provide context for the business, strategy, goals, and culture. These were “front-loaded” as prerequisites for the electronic modules. The goal of making content interesting, making it stick, and making it relevant in the initial eLearning modules – covering Facilities, Microbiology, and Cell Culture – was solid. However, the addition of the Root Learning Map® session really pulled things together in a very sensible and engaging way.

The MedImmune team immediately began working on “deeper dive” technical topics using the same approach: front-load with a Learning Map® module (this time the end-to-end manufacturing process) and then following that experience with eLearning modules. Another dozen modules were developed, covering topics such as Filtration, Purification, and Centrifugation, structured to fit various audiences. Phase 1 was required for everyone in Operations. Phase 2 was required for people working on those processes and optional for all other Operations employees.

Implementation

Twelve electronic modules plus a Root Learning Map® module were rolled out in mid-2009, and another 12 in 2010. In creating the more detailed technical modules, the team at MedImmune initially had a little difficulty in that the specific language and subject matter was unfamiliar to the team at Root. Because the MedImmune team had built such a strong trust and working relationship with them, they found it easy to raise and work through these issues. The team credits Root and their feedback for helping subject matter experts think more about how to present the material to their prospective audience. MedImmune’s Technical Council, a few senior level leaders with deep experience and scientific and technical knowledge, worked closely with Root to resolve issues from strategic and scientific standpoints.

Results

MedImmune calls its results “amazingly positive.” They had planned for an 80% response rate and saw nearly 100% of people completing all the modules. Anecdotal responses were also excellent. Leaders say that they have seen the level of knowledge shifting and growing over time. Members of the Operations Management Team have seen an uptick in knowledge from before and after, and also in the level of interest and depth of conversation. The modules are embedded into the onboarding process as well.

The quality issues that were driven partially by lack of understanding have decreased significantly with very successful regulatory inspections over the last two years. Leadership can visibly see the change in engagement, and the program has acted as a springboard for other learning. As one leader said, “Before, people wanted training so they could learn their jobs, but now they want it because they’re curious to learn! In a technical organization such as ours, the creation of a learning culture is essential for the organization to continue to grow and thrive.”

Disruptive Methods Applied